Gas Spring For Stamping And Injection Molding

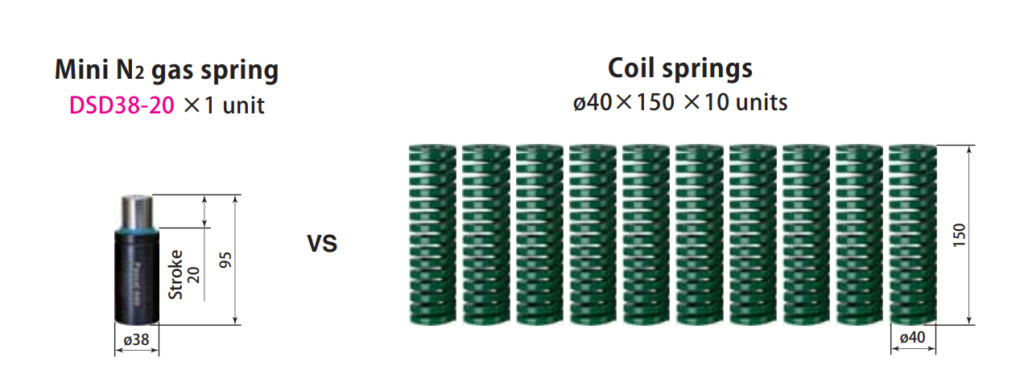

Gas springs are a more powerful, durable, and space-saving alternative to coil springs. Used to apply force and absorb motion or impact, they can provide more force from a smaller volume than is possible with coil springs. This makes them an essential component of stamping and molding tools. One mini N2 gas spring model DSD exerts the same amount of force as ten coil springs, and one model DNA gas spring can exert the same amount of force as six coil springs. Installing gas springs requires less machining time and space because fewer are needed. Coil springs wear down faster with constant compression and decompression, whereas gas springs are much more durable and last much longer.

Model DSD

For stamping and metalforming applications, gas springs hold blanks, support piercing and flanging operations, and activate strippers. In injection molding, they can push ejector plates.

Model DNA (For injection molding)

Your Industrial Gas Springs Company

Pascal manufactures high-quality gas springs. Our company’s gas springs are designed for use with stamping dies and injection molds. Pascal’s gas springs are available in many diameters, stroke lengths and pressures. We also offer long stroke gas springs. With the selection of the gas spring mounts and the micro hose link system, our products fulfill many application requirements.

Gas springs can be plumbed, using a micro hose, adapter, manifold and control panel to create a system with even pressure distribution. The plumbed system also allows the gas pressure to be visualized and monitored.

How Do Gas Springs Work?

A gas spring consists of a rod protruding from a metal body. Inside the body, nitrogen gas held under pressure acts against a piston on the end of the rod. Because they are filled with nitrogen, they are often called nitrogen gas springs.

Pushing the rod into the body increases gas pressure, which results in the spring applying more force. Stroke, force and speed are determined by the diameter and volume of the body, and the pressure preload applied during manufacture.

As gas springs can produce high levels of force from a small size, it’s often possible to use compact versions. Such mini gas springs give tool designers more flexibility in how molding and stamping tools are configured, and even enable the combination of previously separate operations.

Supporting Manufacturers for More Than 40 Years

Pascal is known around the world for components and systems that boost the safety and productivity of molding and stamping operations. Our standard products help manufacturers cut costs, increase output, and offer their customers new features and enhancements.

For less common and particularly challenging applications, we can develop innovative solutions that give our customers advantages over their competition. Browse our website to learn more about our products and services.